Dust Collection - The Ins and Outs

Originally published in 2011 in the Model Railroad Tips email newsletter, re-posted here on Model Railroad Tips 2.0 for your reading pleasure. Author Adam Peszel.

Dust collection has been conducted in industry for well over fifty years, but as the EPA and OSHA became involved particulate and fume control has become more important for all industries. Today, any industry that generates fumes or particulate matter in production uses dust collectors. From simple technologies of settling chambers to more complex technologies of electrostatic precipitation, dust collectors are easy to model and add to the overall effect on your scene.

Inertial Separators

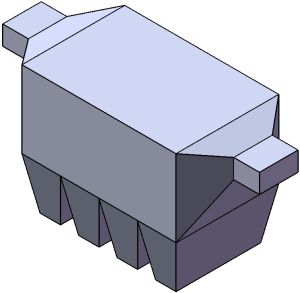

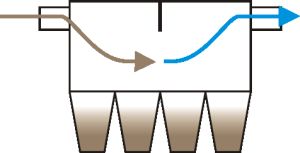

Inertial separators are the simplest concept and probably the earliest in use. These include settling chambers, where the sudden increase in duct volume drops the air pressure and increases the volume that an amount of air can occupy, also dropping air speed. This change causes heavy particulates to drop out of the air stream. Figure 1 shows the basic design of a settling chamber. A duct leads into a large chamber and a duct leads out. On the bottom are hoppers to hold the particulate for easy removal. A related design is the baffle chamber. The general design is like the settling chamber, but internal divider curtains redirect the airflow. As the airflow changes direction, pressure and speed are further reduced allowing better particulate removal. The principle is detailed in Figure 2.

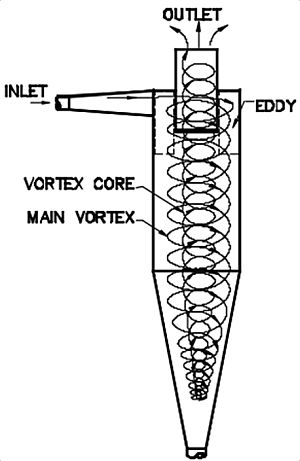

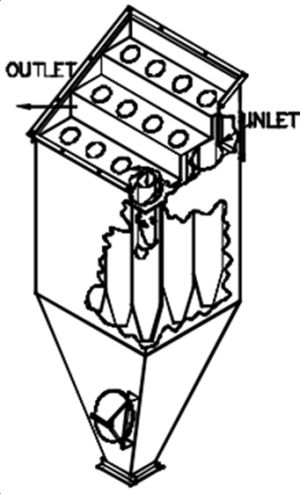

A third type of inertial separator is the cyclone separator. Cyclone separators pull air into a cylinder with a cone on the bottom, see Figure 3. The air stream moves down the outside of the cylinder into the cone. The cone redirects the airstream up into the center of the cyclone and through the outlet at the top. By changing volume, direction and speed of the airstream, the particulate matter drops out into the bottom of the cone. Figure 4 shows a variation of the cyclone, a multi-cyclone. In this application, several cyclones are assembled inside a main housing. The main housing has the inlet from the ductwork and an outlet.

As requirements became more stringent better ways to remove particulate developed. While not suited for all applications, the following types of dust collectors have various benefits over a simple inertial dust collector.

Fabric & Mesh Filters

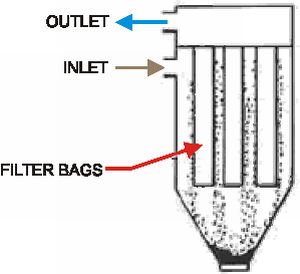

The first type of filter is commonly called a bag house. Bags made of fabric or metal mesh are suspended inside a chamber. Air is fed in to the chamber, typically low in the body, and goes through the bags. Based on the screening size of the bag material, particulate of a certain size and larger do not go through the mesh. For example, a mesh rated at 4 microns will screen particulate that is 4 microns and larger. In this way, a bag house can be compared to most vacuum cleaners used in a home.

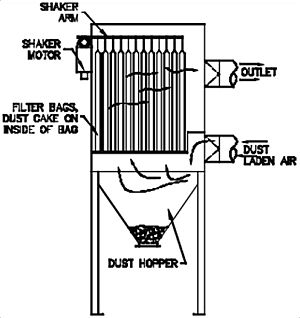

Unlike a vacuum cleaner, bag houses are not intended to have bags swapped out every time they get full or clogged. To clean the bags, a variety of methods exist. The mechanical shaker design shown in Figure 6, consists of a shaker motor which causes a vibration on a shaker arm. The arm in turn shakes the bags, dislodging particulate matter.

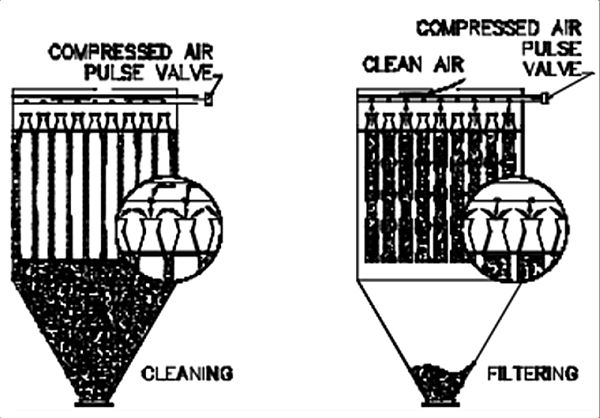

Reverse air and pulse jet designs are related in concept, where a blast of air dislodges particulate matter. The reverse jet design uses a third port where air from outside is blown in counter to the normal air stream and is usually done when the main air stream is shut off for cleaning. The pulse jet uses compressed air inside a header pipe. The header pipe acts as a reservoir and is connected by multiple valves. When the valve is activated, the pressurized air blows down through a section of the bags. This is shown in Figure 7, and when the air stream is at lower pressure than the pressurized air, can be conducted without shutting the air stream off.

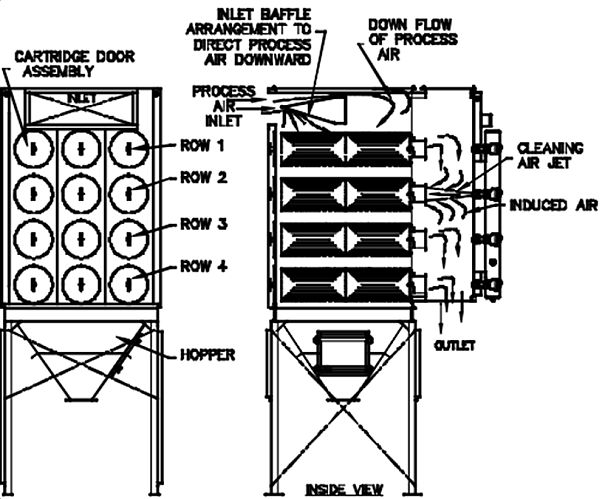

Cartridge style dust collectors are similar to the bag houses, both in general arrangement and processes. Unlike a bag house, cartridge collectors can have the air stream enter at top or bottom, while most standard bag houses are restricted to bottom up air flow. Cartridge collectors have filters similar to a car's air filter and built into a ring. Arrays of these cartridges are aligned with their central axis horizontal, as shown in Figure 8.

Cartridge collectors have two primary cleaning methods. Probably the most utilized is the pulse jet. Like a bag house pulse jet, pressurized air is blown through individual cartridge banks dislodging particulate matter.

When the particulate matter takes time to build up, tends to cling, or cannot be blown off for other reasons, cartridges can simply be removed and disposed of in a proper manner.

Overview

The aforementioned dust collectors all share various similarities. All of these designs use a collection hopper for particulate disposal and have a support structure. In the case large baffle and settling chambers, blowers may be on the inlet side of the collector, whereas individual cyclones, bag houses and cartridge collectors may have the blowers on the exhaust side. In the case of arrays of bag houses or individual multi-cyclones, the blower may be on the inlet side.

Body designs can also vary. While individual cyclones are typically round, most other types discussed are square. The only exception is with bag houses, where some are offered as a round body.

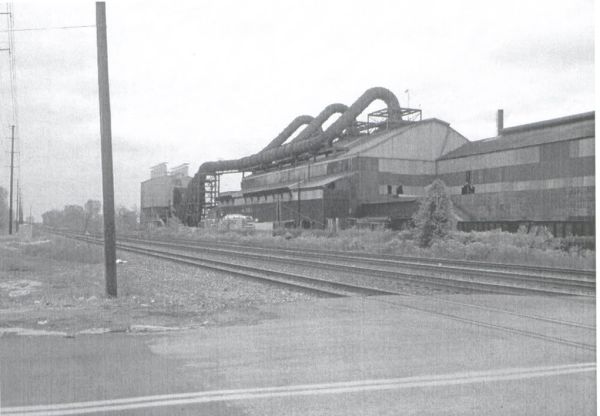

The following pictures show some of these dust collectors installed. Note the ductwork, blowers, structure and walkways for larger systems.

About the Author:

Adam Peszel is a mechanical designer with over a decade designing various machines. Over the past three years, he has been putting his experience to use in writing papers and conducting seminars for model railroaders. Current side projects has him working closely on designs with KenRay Models and St Charles Model Works. He lives in Pennsylvania with his understanding wife and three wonderful children.

Acknowledgements:

Figures 1 & 2, Picture 4: By author

Figures 3-8, Pictures 2 & 3: Compliments of Scientific Dust Collectors, 4101 West 126th Street, Alsip, IL, 60803 USA (Figure 5 was edited by author for legibility)

Figure 3 & 4, Picture 4: Dustex Corporation, 100 Chastain Center Blvd, Suite 195, Kennesaw, Georgia 30144 USA

Figures and Pictures used with permission from respective owners.

©2011/2020, Adam Peszel, https://www.modelrailroadtips.com